We Help Create Solutions

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.

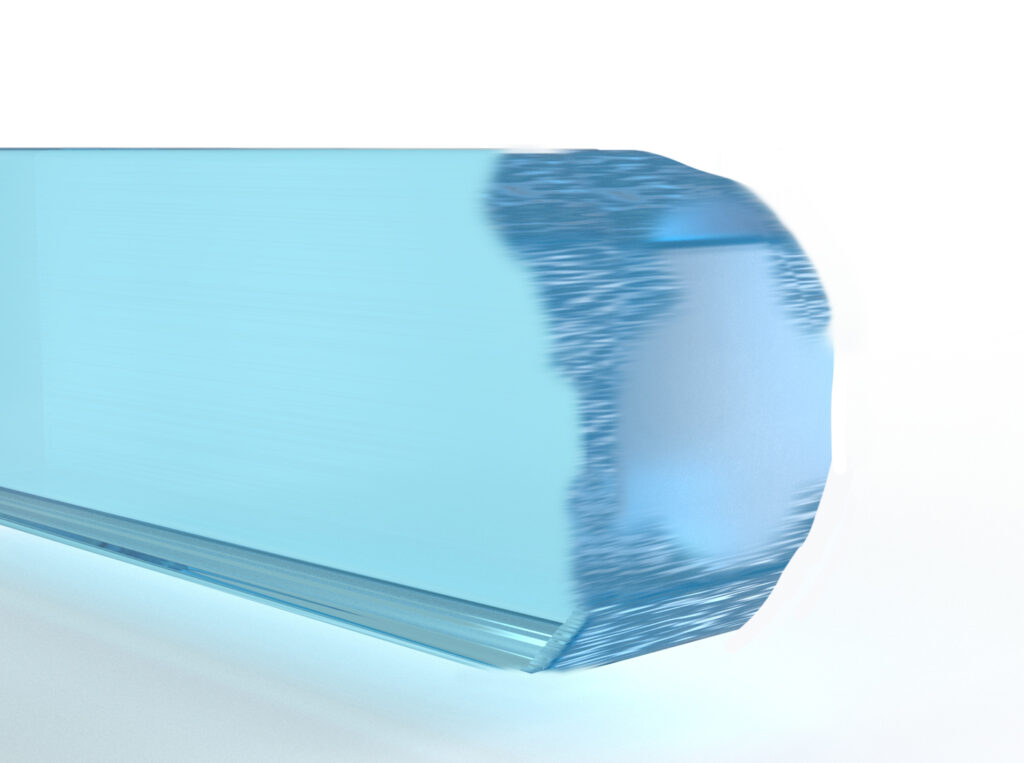

Simplest type. Sharp edges for any cut piece of glass are removed and a belt sander. APPLICATION: Fully Tempered & Heat Strengthened only.

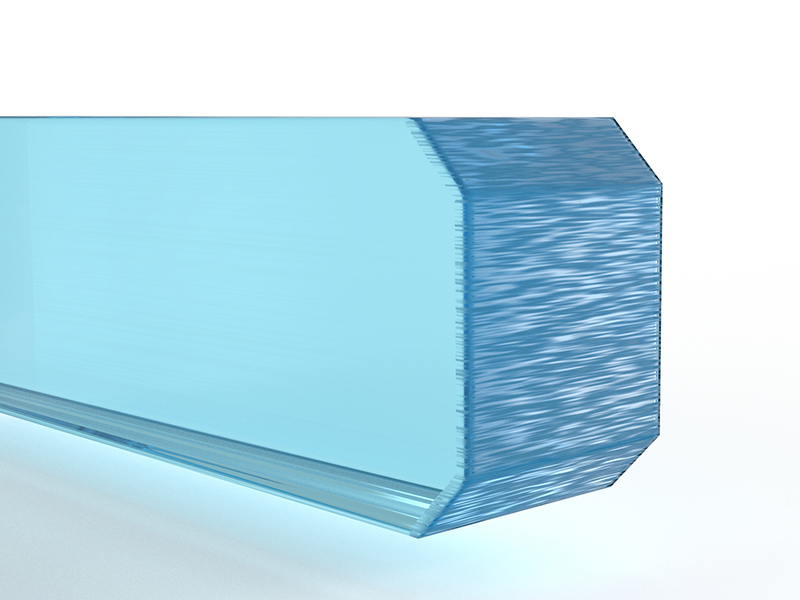

Machined edge of platform with a satin finish. APPLICATION: Butt jointed edges with silicone seal or exposed edges. Fully Tempered & Heat Strengthened only.

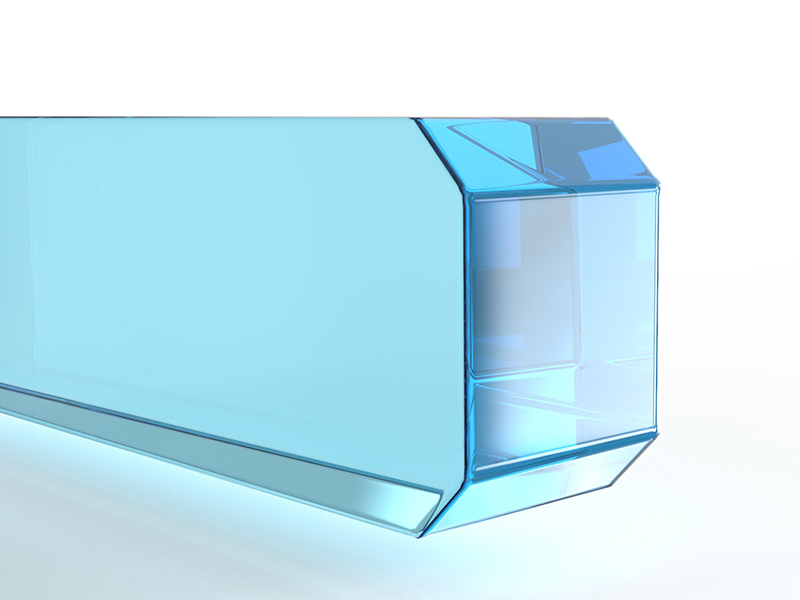

This is a machined edge of flat form with raised edges which has been polished. APPLICATION: Exposed edges.

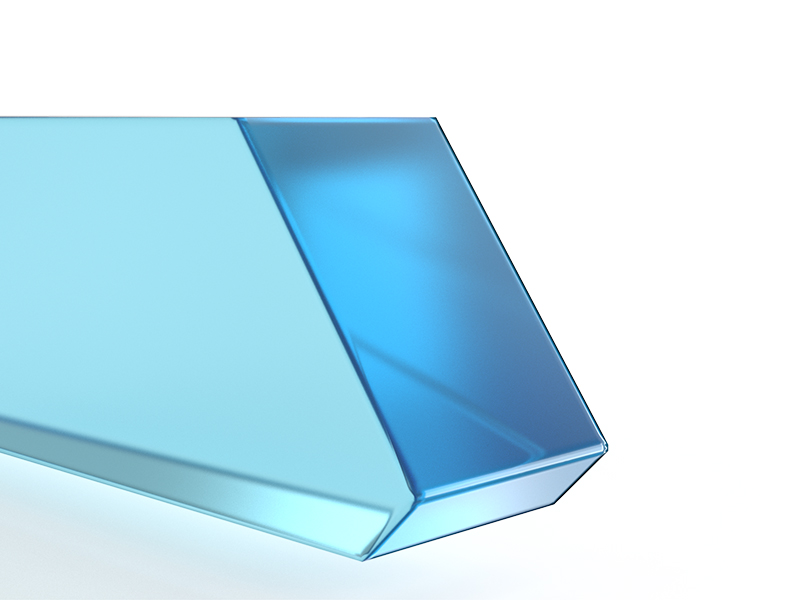

This is a flat machined edge anywhere between a 1° to 45° angle to the cut edge of a panel. The thickness of the glass remaining at the edge is 1/16 of an inch (nominal)

Ground, polished, and mitered edges are available on all heat treated lites and on annealed glass up to 3⁄4” thick. We do not seam annealed glass therefore all annealed glass edges will be sharp.

RIG prefers all fabricated glass products with holes, notches and cutouts to be heat treated.

This is done by using our horizontal jumbo CNC fabrication equipment.The guidelines below also apply for the notch and cutout requirements.

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.