We Help Create Solutions

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.

RIG’s Warm Seal Spacer uses hot-applied thermoplastic technology that chemically bonds the spacer to both the glass and silicone secondary seal on a molecular level. Warm Seal technology has the lowest thermal conductivity available.

Ramapo provides aluminum spacers in Black, Bronze, and Silver/Gray.

• Aluminum provides the most basic level of performance and is most commonly used.

All Metals© provides stainless steel and aluminum.

• Aluminum is offered in Black, Bronze, and Silver/Gray.

• Stainless steel is offered in Black, Bronze, Clear/Silver.

Technoform© is a plastic based spacer that allows for minimal heat transfer and energy/cost savings. Technoform comes in black, gray or bronze.

Under extreme environmental conditions, primary sealants in IGUs can be exposed to high stresses as a result of heavy wind load and extreme temperatures. To compensate, Warm Seal utilizes the whole inner space of the IGU to absorb movements caused by these environmental stresses.

Warm Seal IGUs make it possible to produce absolute height IG units due to the chemical bond created with both the glass and silicone surfaces.

Insulated units may be filled with Argon Gas or Air:

Conventional aluminum, stainless steel, and plastic spacers “short circuit” the edge seal. Warm Seal’s extremely low level of thermal conductivity leads to greatly reduced IGU condensation and improved comfort.

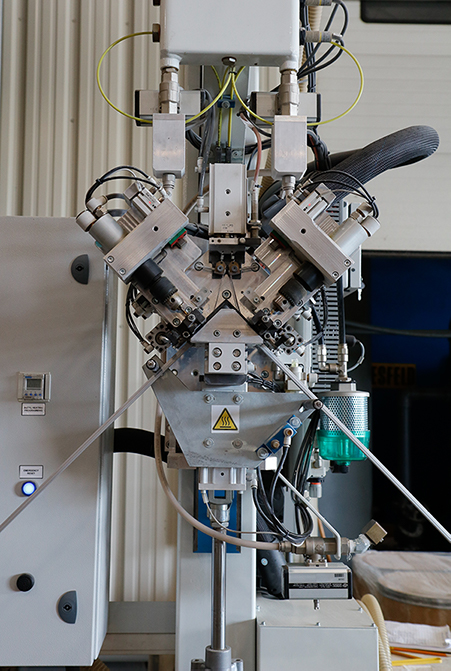

Warm Seal is applied by a CNC-controlled robot directly onto the glass without any manual steps. This allows for positioning with millimeter precision and the flexibility to design unlimited shapes.

Other Warm Seal benefits:

• Non-metal, no glare.

• Straight site-line whereas PIB may migrate.

RIG’s insulated units are constructed with a dual seal configuration. We use PIB (polyisobutylene) as our primary seal and structural silicone as our secondary seal, available in black or grey.

PIB is used to prevent moisture vapor transmission into the space of the sealed unit. The silicone secondary seal acts as an adhesive that holds the unit together. The combination of PIB and silicone seal maintain adhesion to the glass and spacer.

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.