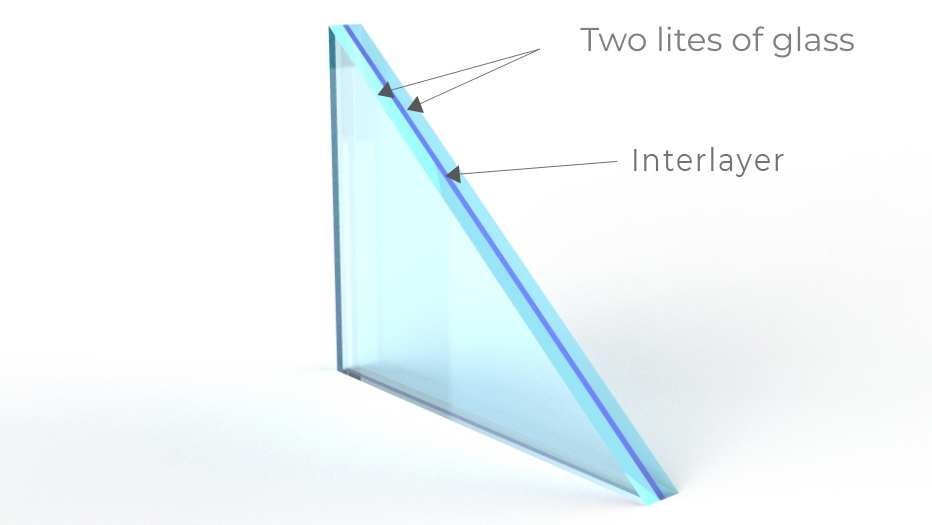

Laminated glass is the result of bonding two or more pieces of glass together with an interlayer using heat and pressure. Variations of interlayers, Polyvinyl Butryal (PVB) or SentryGlas™ (SGP) can enhance safety and security by providing the glass additional strength. There are also options to achieve greater acoustical control and to add color in such a way that tints and coatings are unable to provide.

Laminated glass acts as a strong barrier against outside forces.

Interlayer in laminated units dampen sound characteristics which will overall reduce noise transmission.

Interlayer is available in a variety of colors that may be more aesthetically pleasing in comparison to a coating, substrate, digital-in glass printing or spandrel glass. Opacity may also may be better achieved with a layer of interlayer for a translucent or frosted look. True, bright and vivid colors are represented well in laminated units. Check out Vanceva to see all your color options. [Ordered on a need basis.]

RIG’s lamination process starts in our class 10,000 cleanroom then directly into our customized industry-leading machinery for heat and pressure. We have the capability to produce some of the most unique pieces of laminated glass in the world.

• Our laminated glass can be fabricated in sizes up to 130” x 240” and up to 4” in thickness

• All laminated glass with an interlayer of .030” meets the federal CPSC 16 CFR 1201 category I & II, as well as ANSI Z97.1 class A & B, and CAN/CGB512.1M category I & II

RIG offers a large inventory of standard interlayers in a variety of thicknesses from the standard interlayers thickness from .015” to .100HP” and several specialty layers included STC rated products: