We Help Create Solutions

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.

At RIG, all projects begin with high-quality lites of glass—known as monolithic float glass— typically sourced from domestic float glass providers and, as required, from around the world. We give our customers access to the widest array of glass substrates, tints, sizes, and thicknesses.

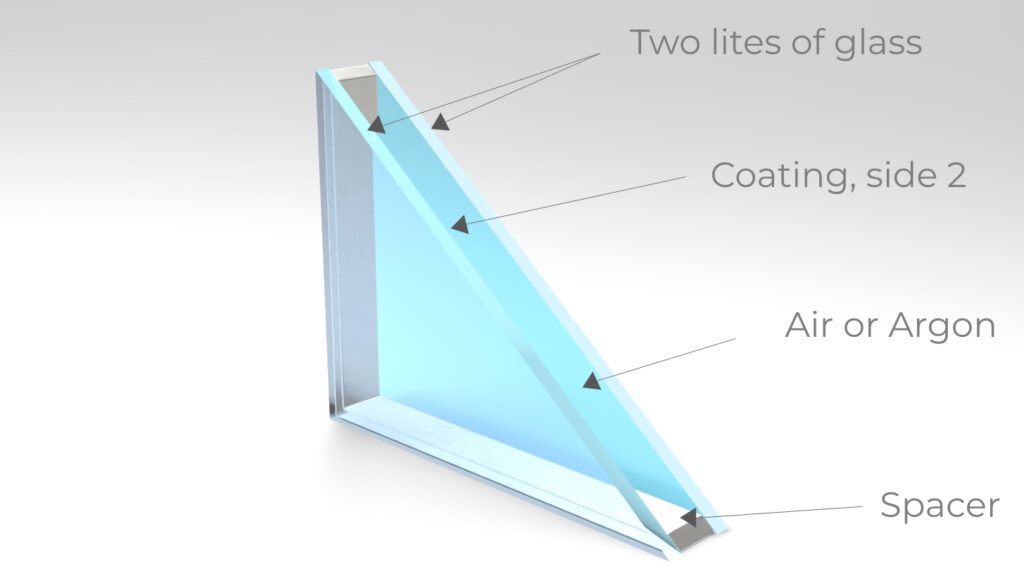

Insulated glass is at the core of RIG.Our process creates a hermetically sealed unit combining two or more lites of glass separated by either traditional spacers or RIG’s signature Warm Seal spacer. Insulation reduces condensation in cold climates and improves thermal performance by scientifically reducing heating and air conditioning costs.

Laminated glass is the result of a process using heat, pressure, and Polyvinyl Butryal (PVB) to bond two or more layers of glass. Different types of interlayers can enhance safety and security by providing the glass additional strength. There are also options to achieve greater acoustical control and to add color in such a way that tints and coatings are unable to provide.

Laminated glass acts as a strong barrier against outside forces.

Interlayer in laminated units dampen sound characteristics which will overall reduce noise transmission.

Interlayer is available in a variety of colors. True, bright and vivid colors are represented well in laminated units. Check out Vanceva to see all your color options.

We’re a full service fabricator that brings your vision to life while adhering to the highest safety and performance standards.